Some people are just begging for attention. Marketers are constantly trying to find ways to build brand awareness, often with clothing -- it's a common practice to make shirts and hats featuring company logos and slogans. To really grab your attention, some companies are using fabric displays -- techniques and systems designed to make dynamic images and text on clothes and other things made of fabric.

There are many different kinds of fabric displays. Some use a still image as a starting point, relying on fabric with special properties to make the design more eye-catching. Other fabric displays can show full video with sound. Each method relies on different technologies, and all have their advantages and disadvantages.

Advertisement

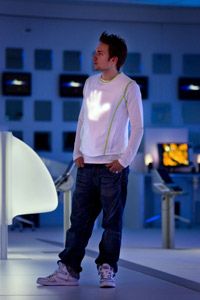

A few fabric display techniques are readily available to the consumer market. Creative individuals have used fabric display technology to build elaborate costumes. Jay Maynard used electroluminescent wire (EL wire) in the costume he built based on the Disney film "Tron" -- his Web page describes how made the costume. His efforts gained national attention, and before long Maynard was making the talk show circuit as "the Tron guy."

In this article, we'll look at the different ways inventors have modified clothing to make a bigger impact on audiences. We'll learn about an idea for fur displays that use electrostatic charges to shocking effect. We'll see how a heat-sensitive dye can turn a normal T-shirt into a very large mood ring. After that, we'll explore the world of electroluminescent clothing. Then we'll see how LED and PLED displays can turn a normal outfit into an eye-catching light display. Finally, we'll learn about companies that have created clothing with built-in television and PC displays.

In the next section, we'll look at a way some engineers plan to use fur to create a dynamic fabric display.

Advertisement