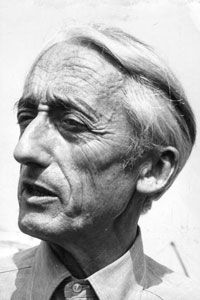

If you've ever seen any of those classic 1970s TV documentaries about underwater adventurer Jacques Cousteau, the father of modern scuba diving, you may have noticed that when he descended into the depths to explore shipwrecks, he didn't just wear some run-of-the-mill watch from the jewelry store bargain bin.

Instead, Cousteau sported a bulky, shiny, complicated -- and incredibly cool-looking -- PloProf diver's watch that he'd actually helped timepiece manufacturer Omega design. But he wasn't just trying to be stylish. Cousteau's watch had super-luminous hour markers and hands set against a dark dial face, which insured that he could make out the time even in low light underwater. More importantly, the watch's stainless steel case and extra-tough mineral crystal were designed to resist water pressure and remain watertight 1,968 feet (600 meters) below the surface, far deeper than even the most accomplished and daring scuba expert would dare venture. It also had a moveable bezel, a ring surrounding the watch face, which made it easier for the wearer to mark the amount of time that he or she intended to spend underwater. And its special, extra-rugged bracelet was touted as shark-proof -- though it's hard to imagine one of those underwater predators trying to nibble it off a diver's wrist [sources: Omega, Coolhunting.com, Richardson].

Advertisement

Cousteau's gadgetry might seem like an antique to today's professional divers. But for both recreational scuba and free divers and ordinary landlubbers who simply enjoy wearing a precision-crafted, elegantly-designed piece of machinery, a diving watch is still de rigueur as an accessory. Publications and Web sites for the watch-collecting subculture are still filled with advertisements for high-end diving watches designed by manufacturers like Certina and Tag Heuer, with prices sometimes in the thousands of dollars [source: Richter].