The little disposable battery testers that you see on batteries or battery packages are a great example of combined technologies -- several existing technologies have been combined in a completely new way! Battery testers depend on two special types of ink: thermochromic and conductive inks. Thermochromic ink changes color depending on its temperature. Conductive ink can conduct electricity. By applying layers of these special inks along with a layer of normal ink using a fairly normal printing press, it is possible to create an extremely inexpensive printed design that changes depending on the amount of electricity it receives.

There are two types of thermochromic ink: liquid crystal and leucodye. Liquid crystal based thermochromic ink is sensitive to very small changes in temperature, but it is fairly difficult to manufacture. This makes it perfect for use in items like thermometers where you need the sensitivity, but troublesome in an item that needs to be inexpensive and in which a large, abrupt change in temperature will occur. Leucodyes are specially formulated substances that change from a specific color, like blue, to a clear state when subjected to a temperature change of about 5 degrees F or more. Thermochromic inks can be formulated to change color at specific temperatures. For battery testers, the desired temperature is usually around 100-120 degrees F.

Advertisement

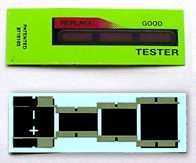

To create a battery tester, you start with a layer of conductive ink that gets progressively narrower as you move across the tester from "good" to "bad." In the picture above the tester has 3 bars. In other testers the ink is wedge-shaped. The narrowest point indicates the weakest charge; the widest area indicates a full charge. When current passes through the thin layer of conductive ink, resistance in the ink creates heat. A small amount of current can generate enough heat to affect the smallest area of thermochromic ink; but, as the area widens, more current is needed to change colors.

On top of the conductive ink is a layer of normal ink that conveys the design. In most battery testers, this is some type of "fuel gauge" graphic or text that indicates that a battery is good. The design can be anything, since the normal ink layer does not affect the way the conductive and thermochromic layers interact.

Finally, there is the thermochromic layer. In the photo of the battery tester above, the thermochromic layer is black when cool. By touching a battery to the conductive ink on the back of the paper, a connection between the positive and negative terminals is created. As a current is generated, the thermochromic ink will turn clear. This reveals the design that is printed in normal ink. If there is enough current, most or all of the thermochromic ink will heat to the temperature needed to become translucent.

One question you might have right now is, "Doesn't the battery tester drain some of the battery's energy?" The answer is, "yes, but not enough to matter." If you tested the battery every 5 minutes it might be a problem, but most people don't do that.

One type of battery tester available now has the tester right on the battery. You press two small dots indicated on the battery to test it. These points complete a circuit between the battery and the tester, and electricity flows through the conductive ink in the same way as in the tester discussed above.

See the next page to learn more about batteries and related information.

Advertisement