If you're into odd techie tricks, it's now possible to use a 3-D printer to make a plastic replica of your own brain. You just get an MRI scan of your head, and then run the data through a program called FreeSurfer. The software creates a three-dimensional surface map of the cerebral cortex that can be used to fabricate a model. But what if you wanted to make actual flesh-and-blood duplicate of your brain?

Doing so might soon be possible through 3-D bioprinting, in which a 3-D printer sprays successive layers of laboratory-grown human cells and uses them to build a piece of tissue or even a complete organ. And while nobody is anywhere close to duplicating an actual functional brain just yet, a recent bioprinting breakthrough by Carnegie Mellon University researchers could bring us a little closer.

Advertisement

–Prof. Adam Feinberg, on the difficulty of printing living brain tissue

CMU associate professor and bioengineering researcher Adam Feinberg says that the newly developed process enables 3-D printers to work with extremely soft materials — for example, human gray matter — and put down layers that remain stable.

"3-D printers have been around for years, but they pretty much print rigid materials — metals, ceramic and polymers that melt for a brief second and then get hard again," he says. "But printing with soft materials such as our own tissue has been a challenge. When you put down a layer, it's been difficult to keep the layer beneath it stable. Imagine a Jell-O mold: The whole thing jiggles. If you're trying to build an intricate biological structure, it's tough because it becomes less stable."

Stopping the Wobble

To solve that dilemma, Feinberg and colleagues figured out how to treat proteins with a special process that pushes them deep into the nooks and crannies of an underlying surface to form a sturdy adhesive bond.

Feinberg previewed the technology at CMU's recent GEM4 Conference, a seminar dealing with some of the latest developments at the nexus of medicine and bioengineering technology. In one session, participants learned how to lay down layers of a collagen gel to create a simulated brain with the same geometry and mechanical properties — such as strength, hardness and ability to stretch or deform — as an actual one.

Such ultra-realistic models, Feinberg says, could be very useful for researchers who are trying to learn more about the damage caused by traumatic brain injuries and how to fix it. Even so, Feinberg emphasizes that there's a big different between creating a gel replica with some brain-like properties and printing an actual human brain. "We're extremely far from that being a reality," he says.

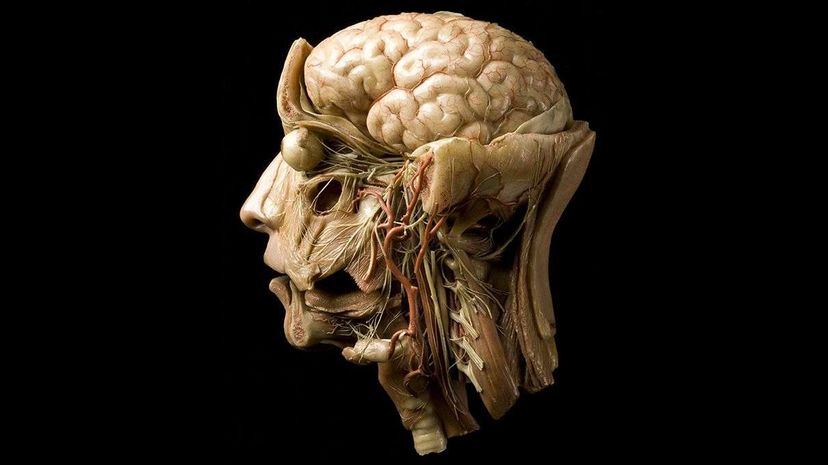

As with many things, the devil is in the details. A typical 3-pound (1.4-kilogram) human brain contains nearly 100 million neurons, with varying structures and highly specialized functions, such as collecting sensory information or transmitting signals that tell the body's muscles what to do. Scientists don't yet have the ability to manipulate stem cells into making all those different types of cells, and even if they did, they still don't know exactly where to put them and how to connect them to duplicate the brain's incredibly intricate neural pathways.

"An MRI scan of a brain can create a 3-D model, but it doesn't have the resolution to show where all those different types of the neurons are," Feinberg says.

Past Printing

In 2013, Oxford University researchers succeeded in bioprinting synthetic nerve tissue — containing tiny droplets of liquid separated by a lipid layer — that can transmit electrical signals in a manner similar to the way your brain does. But those networks are fragile, with a shelf life of a few weeks, compared to the lifetime that brain's wiring will last.

In addition, a real brain also needs a complicated vascular system to provide its cells with nutrients. In 2014, Harvard researchers were able for the first time to bioprint a piece of human tissue interlaced with blood vessels, but they're still far away from being able to replicate the tiny capillaries that living tissue needs.

Finally, even if we get to the point where we can print a complete brain, there's the challenge of actually getting it to function —- to think, remember, develop self-awareness, process sensory information, and do all the other neat tricks that your noggin has been doing since birth. "We don't really understand how that all happens," Feinberg says. "So engineering something that's going to work the same will be very difficult."

Feinberg thinks it's more likely that instead of printing an entire brain, future doctors may print smaller pieces of brain tissue that they can use to replace injured areas.

Advertisement