Ever since Thomas Edison developed the electric light bulb, scientists have looked for better ways to power it. This search has led to major development in two key areas of technology: energy and electronics. The search for ever-better power sources has led to large-scale electric utility services, rechargeable batteries, and devices for harnessing renewable energy from the world around us, such as wind turbines and solar panels. In electronics, developers are continually on the quest for cheaper yet more powerful devices that use less energy than their predecessor technologies.

What if we could produce electricity from the power we generate just by being alive? Imagine if you could keep your iPod charged just by tapping your fingers to the beat of the music or by wearing a hoodie with a tiny embedded circuit board that senses your pulse. Though it might sound like science fiction, nanogenerators are bringing such power sources into reality.

Advertisement

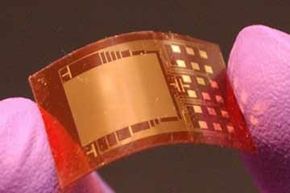

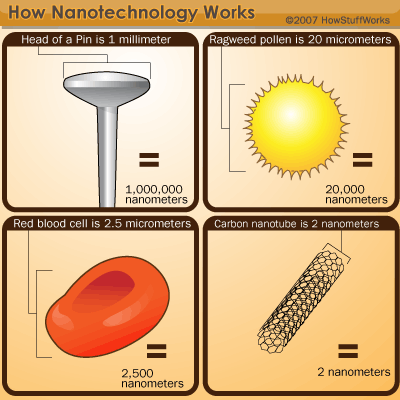

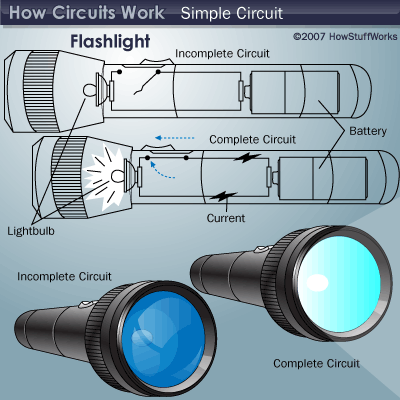

Nanogenerator is the term researchers use to describe a small electronic chip that can use mechanical movements of the body, such as a gentle finger pinch, to generate electricity [source: ACS]. The chip has an integrated circuit etched onto a flexible surface, similar to components on the circuit boards inside your computer. As the "nano-" prefix implies, these generators are a piece of nanotechnology, or technology so small its size is measured by the nanometer (one billionth of a meter). So, even the most complex and powerful nanogenerators in existence today are small enough to be held between two fingers.

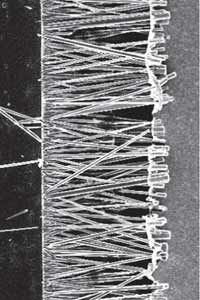

The key components inside a nanogenerator are nanowires or a similar structure made from a piezoelectric ceramic material. Piezoelectric materials can generate an electric current just by being bent or stressed. As described in How Nanowires Work, hundreds of nanowires can be packed side by side in a space less than the width of a human hair. At that scale, and with the combined flexibility of the nanogenerator's components, even the slightest movement can generate current.

Besides being incredibly small and responsive, nanogenerators are increasingly powerful. In March 2011, researchers measured the output of five nanogenerators stacked together. This tiny stack produced a current of about one microampere, which produced three volts of energy, about the same as two AA batteries [source: ACS].

Want to take a closer look at nanogenerator technology and how the practical application of nanogenerators will affect our lives? Let's start with some of the research behind nanogenerators.

Advertisement